294 Energy Scouts Qualified in 2021 – A Brief Review

In April 2021, the second project phase of Young Energy Europe started in eight European countries, from the Baltic Sea to the Mediterranean. The common goal is to qualify Energy Scouts and to advance corporate climate protection. Where do we stand after one year?

The results of the 2021 qualification have been determined

294 Energy Scouts from 108 companies have successfully completed the training in the eight bilateral Chambers of Commerce and Industry abroad. The experienced Chambers of Commerce abroad in Athens, Budapest, Prague and Sofia acted as mentors to the new Chambers of Commerce abroad in Bratislava, Belgrade, Zagreb and Warsaw. The sustainable results of Young Energy Europe are the 125 practical projects of the Energy Scouts of 2021, which lead to lower energy and resource consumption in the companies and thus contribute to the reduction of greenhouse gas emissions.

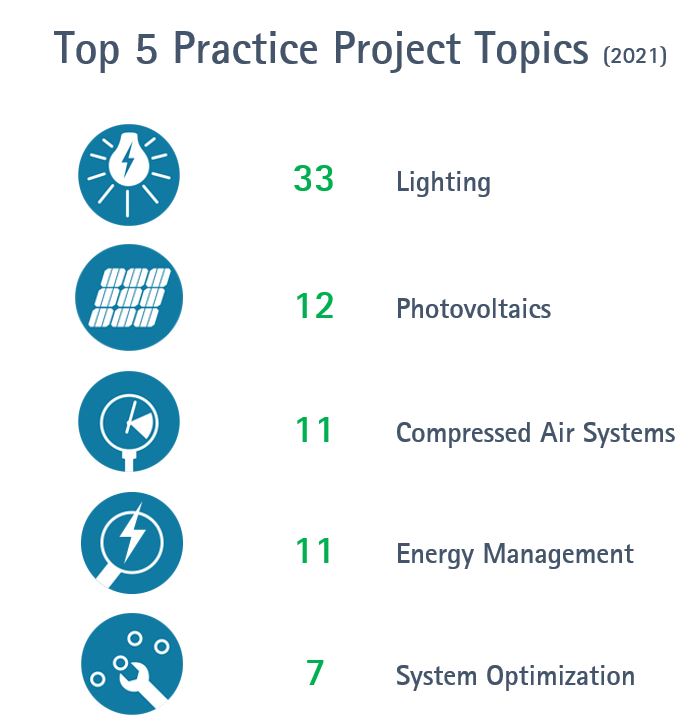

The Energy Scouts designed efficiency projects with significant savings potential, most of them in the areas of lighting, photovoltaics and compressed air.

Further Information

The projects of the year showed a potential reduction of greenhouse gas emissions of around 45,000 t CO2 per year. Behind this are potential savings of around 24,500 MWh of electricity and in some cases considerable amounts of fossil fuels such as lignite, diesel, petrol and natural gas, which the companies are reducing or replacing. Energy Scouts also reduce the consumption of resources such as water, paper and plastics in operational processes. In some cases, waste flows are questioned, recycling is encouraged and even hazardous waste is reduced.

On the one hand, Energy Scouts learn to “scout”, i.e., track down, savings opportunities and efficiency potentials. However, the implementation of an efficiency project in the company is usually dependening on its profitability – which is why the Energy Scouts learn to quantify concrete savings in monetary terms and to calculate payback periods for any investments.

The optimal result, the “sweet spot” in the projects, simultaneously enables cost reductions for the companies, know-how transfer for the employees and a reduction of the environmental impact through optimisation of the CO2 balance & efficient use of resources in the company.